Drilling & Sawing East Sussex

Insured, Site-Ready & Available NowDiamond Drilling & Sawing East SussexEast Sussex

BC Diamond Drilling & Sawing Ltd, renowned experts in sawing and diamond drilling within Surrey, take pride in our team of highly skilled operators proficient in drilling and sawing. We excel in meticulous asbestos management, conducting face fit mask assessments, and operating heavy machinery, including 360 excavators weighing up to 10 tonnes.

Our commitment to effective, dependable, and prompt service is reflected in our well-maintained fleet of equipment. These core principles have been instrumental in our continuous growth, driven primarily by repeat business and referrals, leading to our stellar 5-star reputation.

Our credentials encompass CHAS® Accreditation, Alcumas® Accreditation, PASMA® Certification, along with qualifications in Site Supervision Safety Training Scheme (SSSTS) and Site Management Safety Training Scheme (SMSTS), ensuring top-tier safety and expertise in Surrey’s construction industry.

Accredited & Certified

One-Stop Solution

Reliable & Punctual

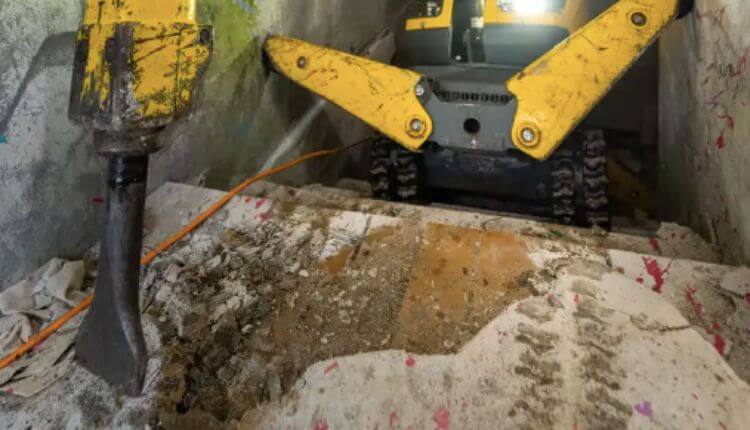

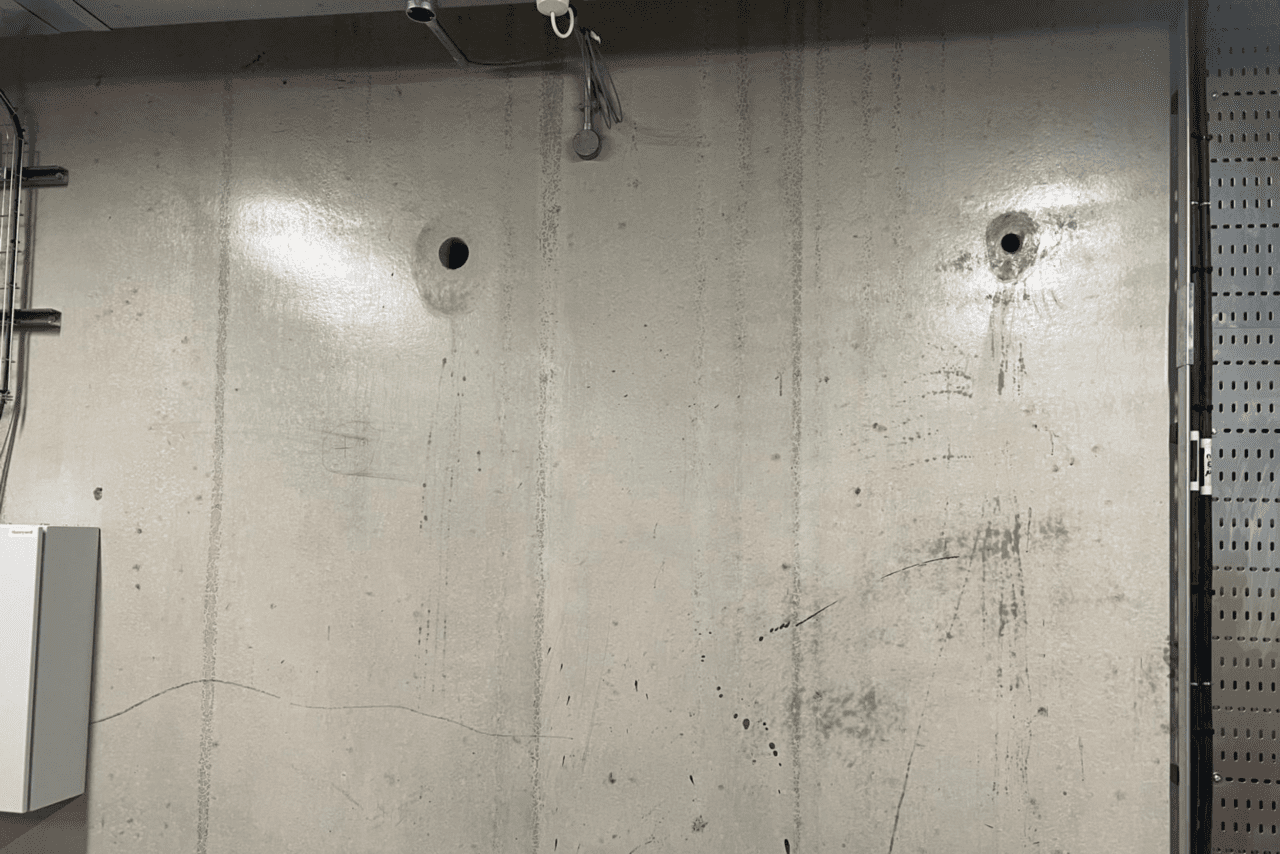

Core Drilling East SussexCore Drilling

Core drilling is a fundamental technique in the construction industry, widely used in East Sussex. This method involves drilling precise cylindrical holes into various construction materials, such as concrete, masonry, and asphalt. At BC Diamond Drilling & Sawing Ltd, we cut holes as small as 12 mm to as large as 1 metre in diameter.

In East Sussex, core drilling plays a pivotal role in construction projects that involve maintaining and restoring historic landmarks. For instance, when restoring the ancient Battle Abbey, core drilling was essential in investigating the structural integrity of its stone walls and foundations. Similarly, when working on the renovation of Hastings Pier, core drilling allowed engineers to assess the condition of the pier’s support columns and decking materials. Moreover, in constructing new structures like the i360 observation tower in Brighton, core drilling creates openings for utility lines and anchor bolts in the tower’s foundation.

Stitch Drilling East SussexStitch Drilling

Stitch drilling is a valuable technique within the construction industry, commonly employed in East Sussex. This method involves drilling closely spaced holes along a defined line, typically used for cutting openings in concrete, masonry, or other robust building materials. As a core drilling technique, we can stitch holes from 12 mm in diameter.

In East Sussex, stitch drilling is instrumental in construction projects that involve restoring and preserving historical landmarks. For instance, when refurbishing the ancient Battle Abbey, stitch drilling creates precise openings for new doors or windows, allowing for structural improvements while maintaining heritage aesthetics. Similarly, in the maintenance of the De La Warr Pavilion in Bexhill-on-Sea, stitch drilling assists in installing modern utilities while preserving the integrity of the original concrete structure. Furthermore, in constructing modern infrastructure like the Newhaven swing bridge, stitch drilling is employed to make openings for railway tracks, ensuring the safe and efficient operation of the transportation system.

Controlled Demolition East SussexDemolition

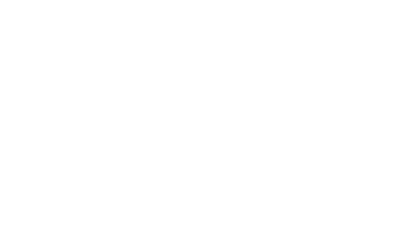

Controlled demolition is a highly specialised technique in the construction industry, often utilised to safely and efficiently dismantle structures, especially in densely populated or historically significant areas like East Sussex. One remarkable tool in controlled demolition is the Brokk machine, a remote-controlled robotic demolition system known for its precision and safety.

In East Sussex, landmarks like the abandoned Hellingly Hospital have benefitted from using Brokk machines during their demolition processes. These robots can access tight spaces and remove concrete, steel, and other materials without the risks associated with traditional methods.

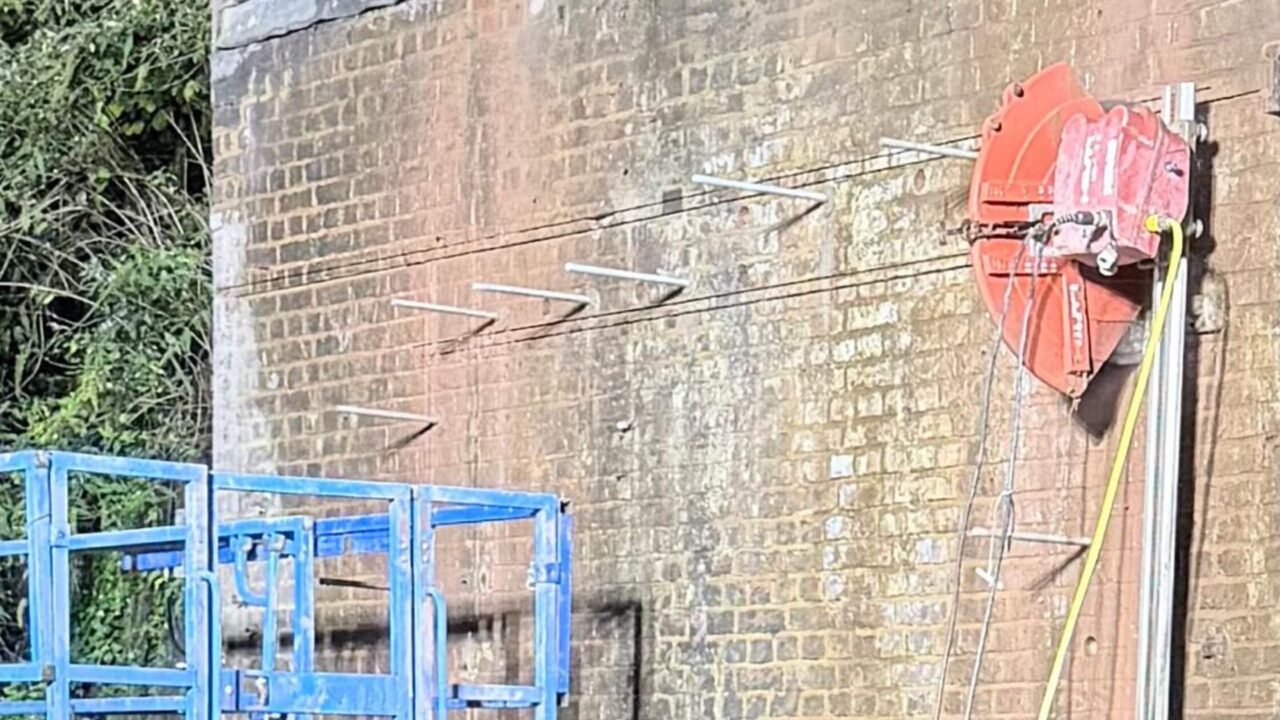

Wire Sawing East SussexWire Sawing

Wire sawing is a versatile and precise cutting method widely employed in the construction industry, with numerous applications in East Sussex’s landmark preservation and renovation projects. This technique utilises a flexible wire embedded with diamond beads to cut through a variety of materials, including concrete, steel, and stone, with minimal noise and vibrations.

In East Sussex, landmarks like the historic Lewes Castle have benefited from wire sawing during restoration efforts. The method allows for the careful removal of deteriorated sections of stone walls while preserving the original structure’s integrity. Similarly, in projects such as the repair of the Rye Harbour Arm, wire sawing is employed to cut and remove damaged or deteriorated concrete precisely, ensuring the safety and functionality of the harbour’s infrastructure.

Floor Sawing East SussexFloor Sawing

Floor sawing is a critical technique in the construction industry that involves using specialised equipment to make precise horizontal cuts into concrete or asphalt surfaces.

In East Sussex, floor sawing has been instrumental in maintaining and preserving historical landmarks like the iconic Hastings Pier. During its renovation, floor sawing was employed to create clean and precise openings for utility installations and to remove damaged sections of the pier’s decking while preserving its structural integrity. Additionally, floor sawing plays a crucial role in the construction of modern infrastructure, such as the Eastbourne Marina, where it is used to create expansion joints and trenches for utility lines, ensuring the longevity and functionality of these developments.

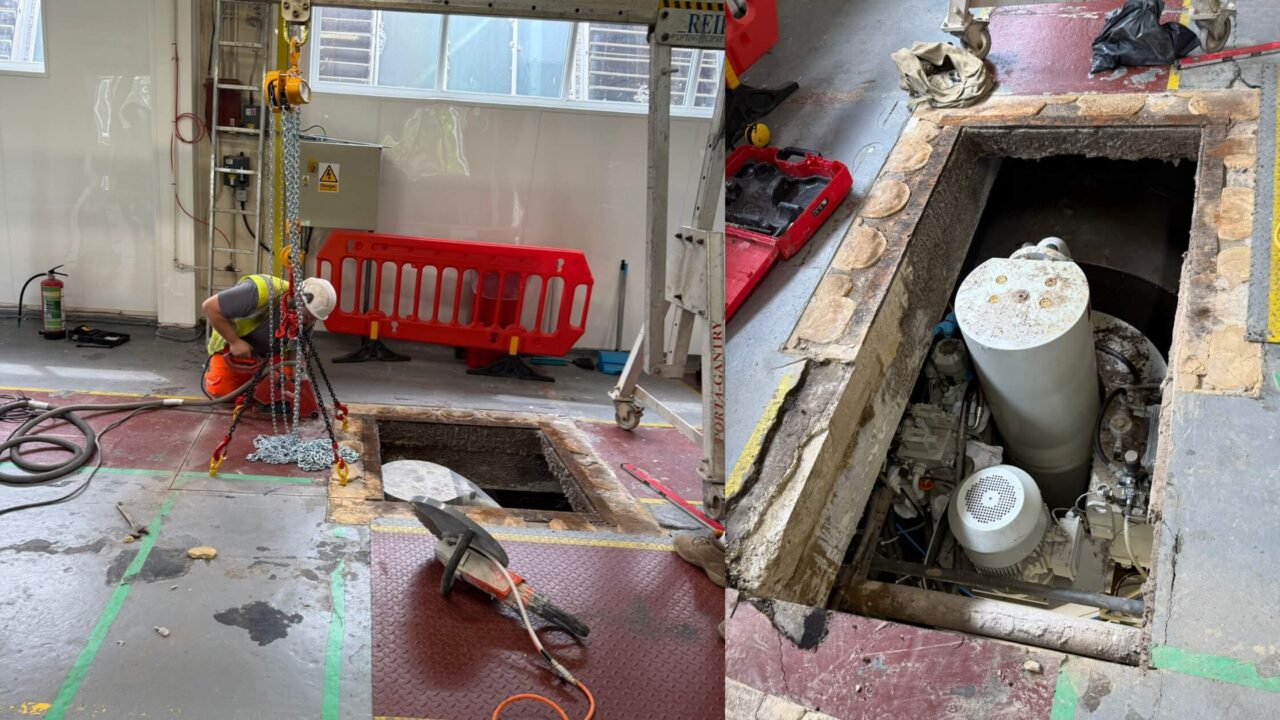

Wall Sawing East SussexWall Sawing

Wall sawing employs specialised equipment to create precise and controlled cuts in vertical or inclined surfaces, typically made from concrete, masonry, or other hard materials.

In East Sussex, wall sawing has been vital in restoring historical landmarks like Bodiam Castle. During the castle’s renovation, wall sawing was utilised to carefully remove deteriorated sections of the stone walls while preserving the structure’s authenticity. Additionally, in projects like the construction of the Bexhill Museum extension, wall sawing was employed to create openings for windows and doors in existing concrete walls, seamlessly blending the old and new architectural elements.

Ring Sawing East SussexRing Sawing

Ring sawing employs a ring-shaped, diamond-tipped blade to create precise and deep cuts in various materials, including concrete and masonry.

This technique has been employed in projects like the restoration of Herstmonceux Castle. This historic landmark required intricate modifications, and ring sawing was used to cut through thick stone walls, enabling the installation of modern amenities while preserving the castle’s structural integrity. Similarly, in the maintenance of Eastbourne Pier, ring sawing has been utilised to safely remove damaged or deteriorated sections of the pier’s concrete deck.

100% Satisfaction

Maintained Equipment

24-Hours

Site-Ready Team

Request a Free Quote for Your Project

Based in Hastings, East Sussex, we travel across the South East of England, including Greater London, Essex, Surrey, Kent, East Sussex and West Sussex, for big and small construction projects. BC Diamond Drilling & Sawing Ltd have the knowledge, skills and industry expertise to undertake a wide range of diamond drilling and cutting services. We take it a cut further, emphasising safety and minimising environmental impact. So, if you’d like professional sawing and drilling contractors you can rely on every time, request a free, highly competitive quote today.

East Sussex Service Areas

Bexhill-on-Sea, Brighton, Crowbrough, Eastbourne, Lewes, Newhaven, Rye, Seaford, Uckfield